Specialized for production environments with aerosol oils or syrup residue. Examples include: cola bottling plants, high truck and forklift traffic, cutting lubricants, and sulfur (metallurgy). DS 612 filters provide the optimal bonding surface to capture oils, greases and contaminants from exhaust vapor and fumes.

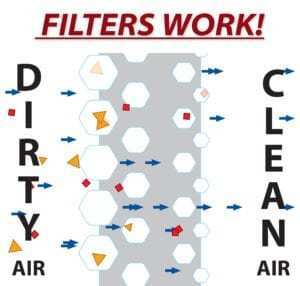

DustShield enclosures cannot protect your equipment without clean filters.

The DustShield fan/filtration system pulls in air through the filter which traps the dust and oil forcing clean air to circulate around the enclosed components before the air is pushed out through the exhaust and cables ports. This positive pressure air flow system helps to cool the enclosed components while protecting the enclosed items from dust, dirt, oil and other environmental contaminants.

Routinely changed, clean filters remove more than 98% of all contaminants and are 6x more effective than permanent, washable electrostatic filters.

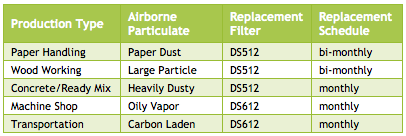

How Often to Replace Filters?

Replace dirty computer cabinet filters monthly or bi-monthly depending on the harshness of your production environment. Here are replacement schedules for some common industries:

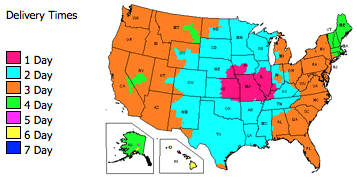

Delivery Times